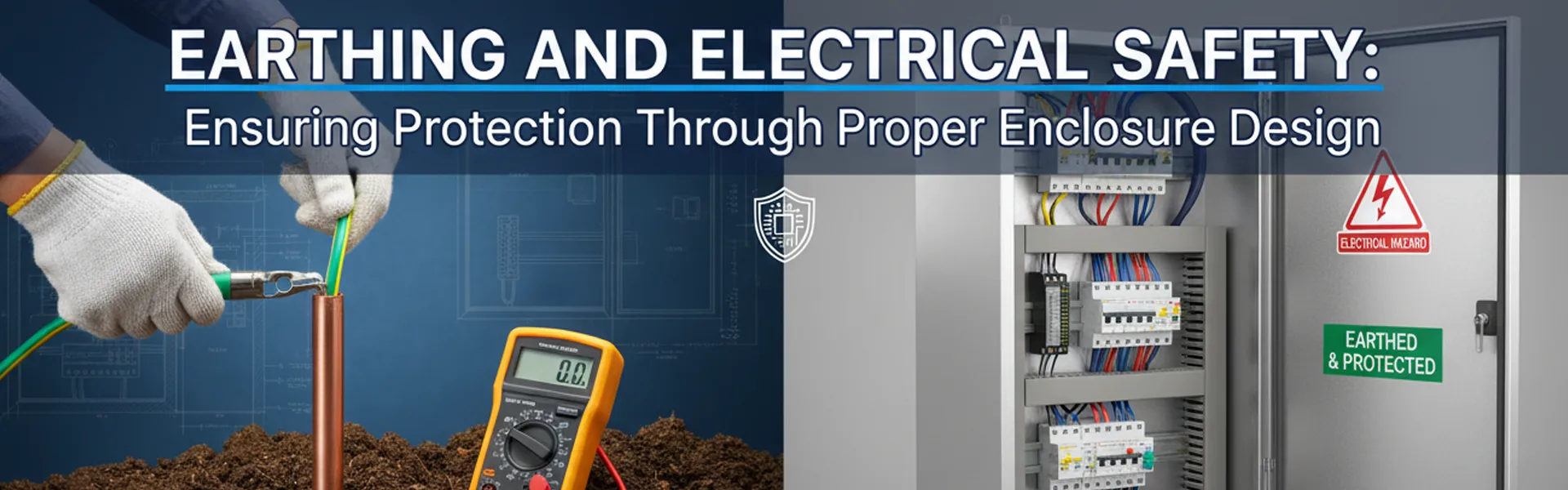

Earthing and Electrical Safety: Ensuring Protection Through Proper Enclosure Design

When it comes to electrical systems, safety is never optional—it’s a necessity. One of the most critical components of electrical safety is earthing. Whether in residential, commercial, or industrial environments, properly designed electrical enclosures and earthing systems protect both operators and equipment from severe hazards. Let’s explore the importance of earthing, the regulations surrounding it, and how enclosures are designed to meet the highest safety standards.

Why Electrical Enclosures Need Earthing

The primary function of an electrical enclosure is to ensure the safety of both operators and the equipment housed within. Even with careful design and advanced safety planning, unwanted short circuits are a reality of electrical systems. These faults can cause serious risks, including electrical shocks, fires, or equipment failure.

Earthing provides an additional, safe pathway for electrical current to flow back to the ground in the event of a fault. Instead of traveling through a person or equipment, the current is diverted into the ground, often causing a fuse to blow or a circuit breaker to trip. This controlled reaction is far safer than allowing uncontrolled current flow, which could otherwise be fatal.

Earthing Standards and Regulations

Earthing is not just best practice—it is mandated by international standards to ensure consistent levels of safety. Some key standards that outline the requirements for earthing in electrical enclosures include:

EN 62208 – Empty enclosures for low-voltage switchgear and control gear assemblies.

EN 61439-1 – Low-voltage switchgear and control gear assemblies: General rules.

EN 60204-1 – Safety of machinery: Electrical equipment of machines.

These standards establish requirements for the design, testing, and performance of enclosures, ensuring that they can safely conduct fault currents and protect people and property.

Verifying Earth Continuity

To confirm the reliability of an enclosure’s earthing system, specific tests are conducted. One such test verifies that all exposed conductive parts of the enclosure are effectively connected to the earthing terminal or protective circuit. The resistance of the circuit must not exceed 0.1 Ohm.

This is measured using a resistance testing device capable of driving a current of at least 10 A (AC or DC). By measuring the voltage drop across the system and calculating the resistance, engineers can confirm that the earthing connections meet the required safety standards.

Designing for Earth Continuity

Well-designed enclosures are built to ensure earth continuity even during operation or routine maintenance. For example:

Removable Parts: When a panel or section of an enclosure is removed, the protective earthing for the rest of the enclosure remains uninterrupted.

Doors, Lids, and Covers: Metal hinges and screw connections generally provide sufficient continuity if only low-voltage equipment is attached.

Higher Voltage Equipment: If equipment operating above extra-low voltage is mounted on doors or covers, additional earthing measures must be taken. This can include attaching protective conductors or using corrosion-protected sliding contacts or special hinges.

These provisions ensure that no matter the configuration, exposed conductive parts remain safely bonded to the earthing terminal.

Contact Resistance and Current-Carrying Capacity

One important requirement is that the contact resistance of all interconnected parts in an enclosure does not exceed 0.1 Ohm. Achieving this low resistance ensures that fault currents can safely flow through the earthing system without interruption.

For enclosures with doors or panels carrying equipment rated above 16 A, it is often recommended to add a separate earth conductor. This ensures full protection against indirect contact risks, especially when dealing with higher loads.

Achieving Reliable Earthing in Enclosures

Reliable earthing is achieved through careful construction and the use of high-quality materials. Common methods include:

Paint-masking of touching surfaces – Ensuring that conductive surfaces remain exposed where they meet.

Dedicated earthing components – Such as bolts, straps, or lugs specifically designed for earthing.

Self-tapping screws with earthing features – Designed to cut through paint layers and establish metal-to-metal contact.

Earthing washers and serrated nuts/bolts – Providing secure conductive connections even under mechanical stress.

These measures ensure that painted or coated surfaces, which might otherwise insulate parts of the enclosure, still provide reliable electrical continuity.

Why Earthing Matters

Electrical safety isn’t just about compliance—it’s about protecting lives and property. A properly earthed system ensures that:

Fault currents are safely carried away.

Circuit breakers or fuses operate as intended.

Operators and maintenance personnel are protected from electric shock.

Equipment damage and fire risks are minimized.

Ultimately, earthing transforms a potentially catastrophic fault into a manageable, controlled safety event.

ABOUT US

At Abyad Al Nasea Electricals Trading LLC, we understand the importance of reliable electrical solutions that prioritize safety. As one of the leading and trusted suppliers of electrical and electronic products across the United Arab Emirates, we are proud to provide top-quality equipment for residential, commercial, and industrial use.

Recognized as a top electrical equipment supplier in Dubai, we are committed to delivering durable and efficient solutions tailored to the needs of our valued clients. Our approach goes beyond just supplying products—we focus on building strong, lasting relationships with our customers by offering customized solutions that meet their exact requirements.

From small-scale residential projects to large industrial operations, our team works together with clients to create outcomes we can all be proud of. Our portfolio includes a wide range of electrical and electronic equipment, ensuring we have the right solutions for every job, project, or application.

At Abyad Al Nasea Electricals Trading LLC, we are more than just suppliers—we are partners in building safer, smarter, and more reliable electrical systems across the UAE.

Conclusion

Earthing remains one of the most vital aspects of electrical safety, and enclosures play a central role in ensuring effective grounding. By following international standards, conducting rigorous testing, and employing smart design practices, electrical systems can safeguard operators, equipment, and property from harm.

With the right products and solutions from trusted suppliers, you can be confident that your electrical systems are built to last—safe, efficient, and future-ready.